Chamber Filter Press

Chamber Filter Press is one such form of filter press that has found wide application in the process of solid-liquid separation across various industries.

- Meet different process needs and specific customer needs.

- The high level of setup and most flexibility

- The small and stout design allows for perfect and reliable filtering.

- High level of security implicated due to the involvement of latest security techniques.

Product Description

Chamber filter press: High efficiency filter press

The chamber filter press is a form of filter press that has been widely applied in the separation of solid and liquid across different industries. They are also widely applied in treatment plants, mining operations, chemical industries, and food processing plants. Through this process, the liquid portion is pushed through the filter cloth, with the solid particles remaining inside the chambers.

The filter press chamber type typically consists of a simple structure in filter plates and filter cloths. With solid plates in between, these are arranged. Our product’s plates are normally made from materials such as polypropylene, cast iron, or stainless steel, depending on how it is going to be used and what is to be filtered. Each plate has a central space or chamber where solids accumulate upon filtration.

Chamber filter press advantage

- High Filtration Efficiency: We implement advanced filtering methods, like careful placing of filter cloth and improved plate design, to ensure efficient and effective filtering.

- Durable and Long-Lasting Construction: Filter plates are typically manufactured from robust polypropylene with other materials or from non-corrosive materials.

- Sealing Performance: Chamber filter presses are equipped with reliable sealing systems to avoid leaks and assure a homogeneous application of pressure during filtration.

- Easy to use: it has automatic or semi-automatic control systems that make usage easier, with little human assistance.

- Diverse Applications: Supplies alternatives to customize the filter presses for different process requirements.

Filtration Principle

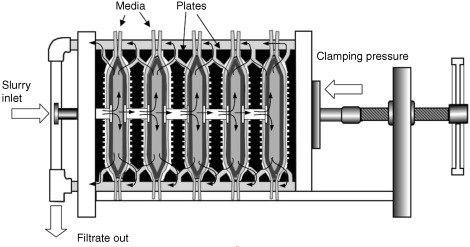

The filter cloth provides the media through which the liquid can pass while the solids are held back. As a result of this, filter cakes form in the chambers, and the filtrate is collected to affect efficient solid-liquid separation.

- Filtration: Chamber filter press utilizes the pressure on the slurry. The pressure may be provided by hydraulic or mechanical means. It forces the liquid portion to pass through the filter cloth while retaining solid particles in the chambers.

- Cake formation: The liquid passing through the filter cloth, the solid particles forming a layer, on the surface of the cloth in each chamber.

- Filtrate collection: The liquid fraction of the slurry, called filtrate, passes through the filter cloth and collects in the drainage system or collection channel.

- Cloth Cleaning: Over time, the filtering cloths become clogged up with dirt and solids that reduce the efficiency of filtration. The filter cloths need regular cleaning or changing to maintain a well-functioning chamber filter press.

Applications of chamber filter press

- Wastewater treatment: Chamber filter presses have a wide range of applications in the treatment of wastewater from cities and factories. This greatly helps in minimizing sludge disposal while producing cleaner water.

- Mining and minerals: these chamber filter presses are very essential in the mining business, which helps in drying out mining slurries to recover valuable minerals. These can effortlessly segregate solid materials from mining waste, slurry concentrates, and other mining liquids. Chamber filter presses play an important role in the management and disposal of the solid waste generated by removing water from slurry. They provide a way for recovering water and useful minerals.

- Chemical Industry: Chamber filter presses improve product quality, reduce waste, and enhance the effectiveness of the chemical manufacturing process.

- Food and Beverage: The food and drink industry uses chamber filter presses for various jobs. Also, chamber filter presses help take out solids, particles, and impurities, making sure the product is clear and of good quality.