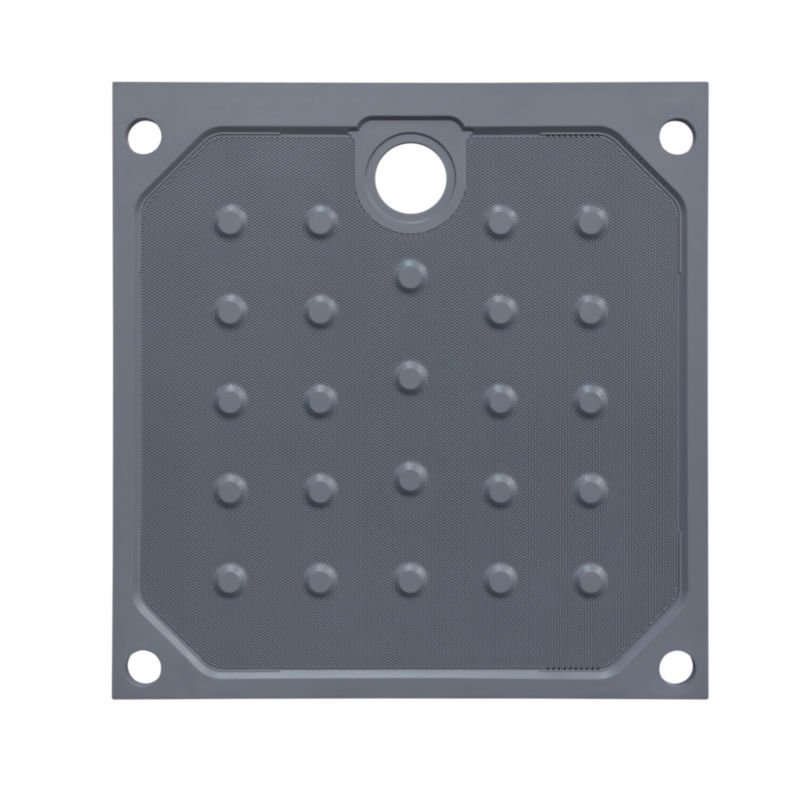

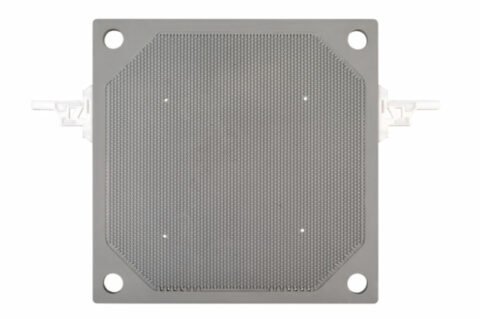

2500×2600 Recessed Plate

Filter plate is the core part of the filter press. Different materials, models, and qualities will affect the whole machine’s filtration performance directly.

Product Description

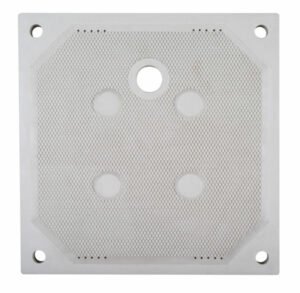

The filter plate is the core part of the filter press. Different materials and quality directly influence the whole filtration performance of the filter press. According to the use of different materials, there are various designs about the feeding hole, filter points distributing in the plate and water discharge channels. Filter plate adopts imported TPE elastomer and high intensity PP. Those make the filter plate not only has the flexibility of rubber plate, but also the tenacity and rigidity of polypropylene plate that ensure the airtightness of the filter plate during pressing. All technical indexes of filter plates strictly comply with EU standards. The maximum membrane inflation pressure of high-pressure PP membrane filter plates can be up to 4.0 MPa, representing the most advanced level of the world.

Quick Details

| Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Construction works , Food & Beverage Shops |

|---|---|

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Marketing Type: | Ordinary Product |

| Warranty of core components: | 1 Year |

| Core Components: | Pressure vessel |

| Place of Origin: | Guangzhou, China |

| Material: | PP and reinforced pp |

| plate thickness: | 75 |

| chamber: | 15 |

| cake: | 30 |

| filtration area: | 4.67 |

| After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

Membrane plate

Membrane plates bring superexcellent filtration effect and unimaginable benefits.

The solid content can be controlled by the squeezing pressure.

Squeezing twice after completion of filtration can improve the solid content of the cake.

Membrane plate can carry out “Low pressure for filtration, higher pressure for squeezing.” Improving life-span and reducing energy consumption.

Improved washing effect, shortened washing time, saved washing liquid, and improved quality of products.