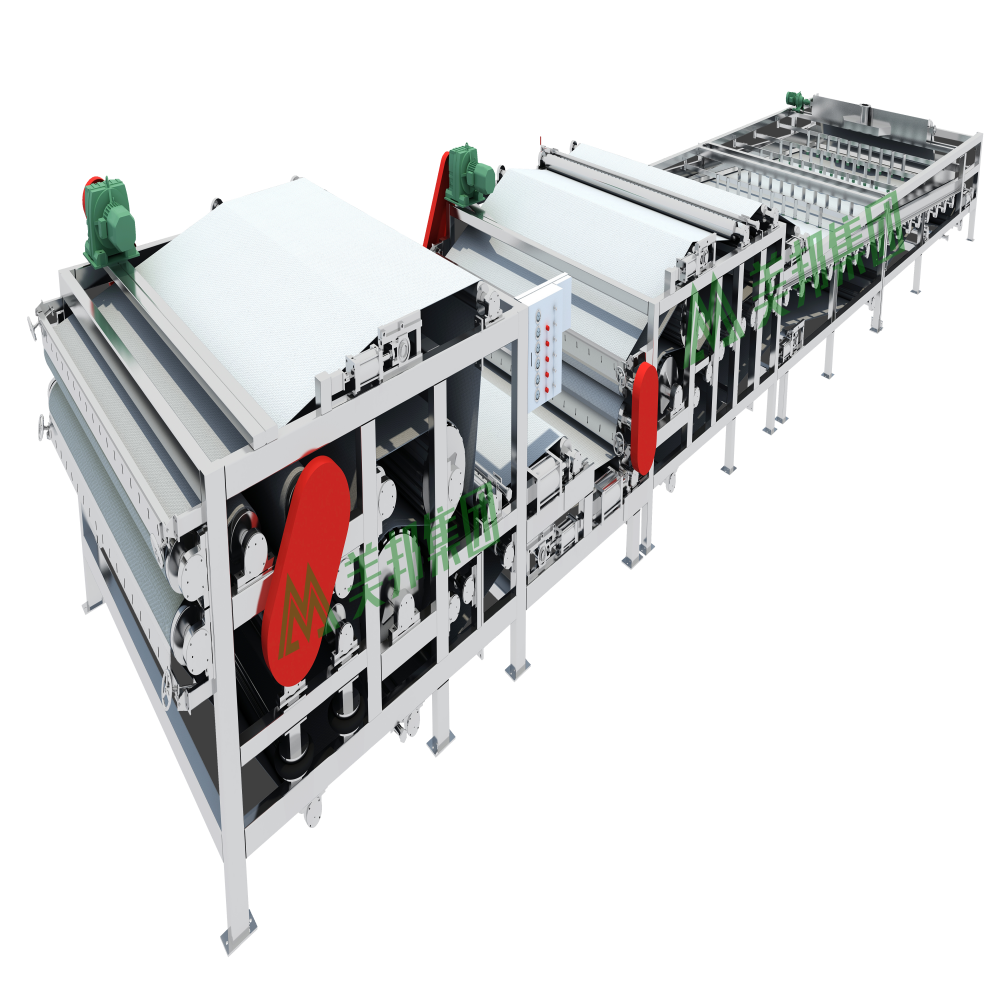

Four-Belt Filter Press for Industrial Wastewater Treatment

-

Four-Belt High-Pressure Pressing Design

Multiple pressing zones significantly enhance dewatering efficiency for difficult-to-dewater industrial sludge. -

Optimized for Industrial Wastewater Sludge

Suitable for sludge generated from chemical processing, food production, fermentation, and other industrial wastewater treatment processes. -

Continuous and Stable Operation

Designed for continuous feeding, pressing, and cake discharge, ideal for industrial plants with steady sludge output. -

Durable Construction for Industrial Environments

Heavy-duty frame and corrosion-resistant components ensure long service life in harsh and chemically aggressive conditions. -

Easy Operation and Maintenance

Open structure allows convenient filter belt cleaning, replacement, and routine inspection, reducing downtime and labor requirements.

Four-Belt Filter Press for Industrial Wastewater Treatment

Product Overview

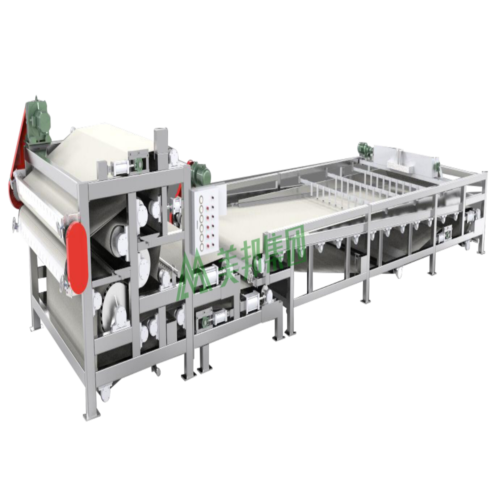

The Four-Belt Filter Press for Industrial Wastewater Treatment is a high-performance sludge dewatering machine designed specifically for industrial wastewater treatment systems, including chemical plants, food and beverage processing facilities, paper mills, breweries, and other process industries.

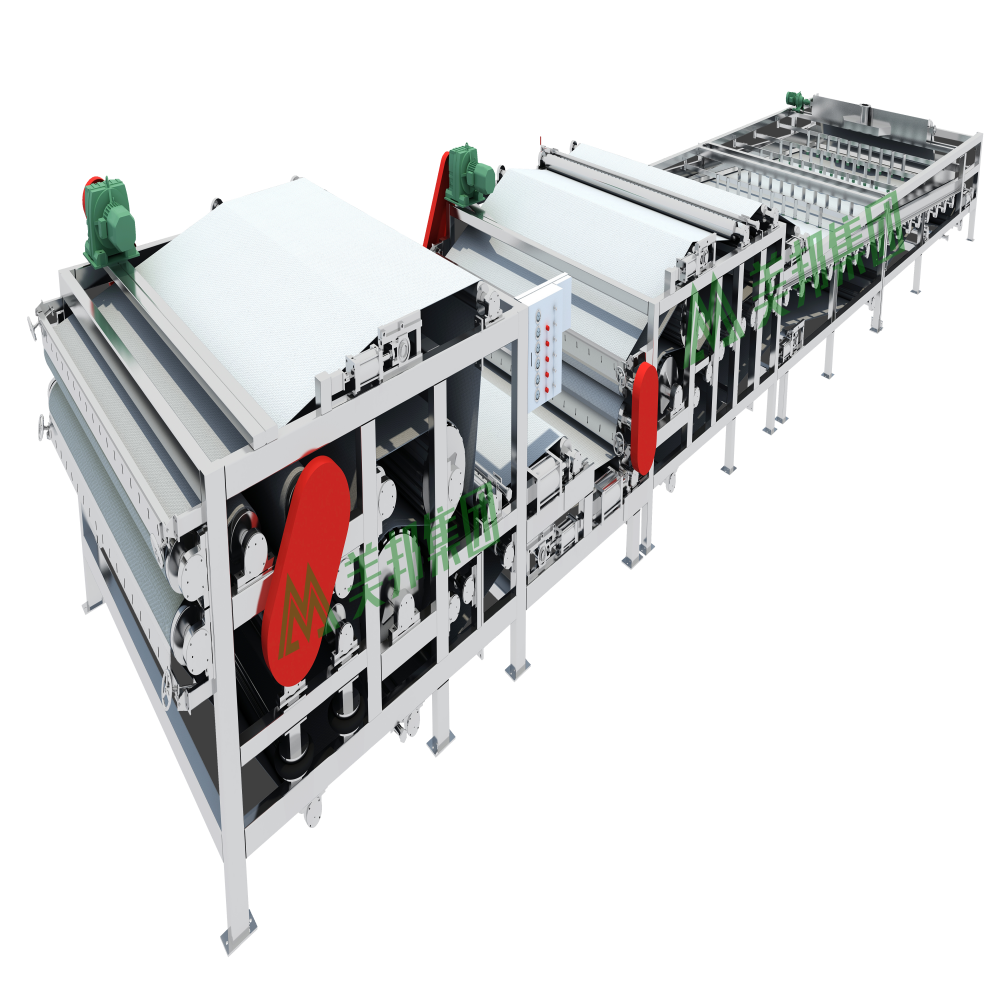

Featuring a four-belt pressing structure, this equipment provides stronger squeezing and shear forces, making it highly effective for treating industrial sludge with high organic content, high viscosity, or complex chemical composition. Compared with conventional belt filter presses, it delivers lower sludge cake moisture content, higher solids recovery, and more stable continuous operation, even under demanding industrial conditions.

Key Features

-

Four-Belt High-Pressure Pressing Design

Multiple pressing zones significantly enhance dewatering efficiency for difficult-to-dewater industrial sludge. -

Optimized for Industrial Wastewater Sludge

Suitable for sludge generated from chemical processing, food production, fermentation, and other industrial wastewater treatment processes. -

Continuous and Stable Operation

Designed for continuous feeding, pressing, and cake discharge, ideal for industrial plants with steady sludge output. -

Durable Construction for Industrial Environments

Heavy-duty frame and corrosion-resistant components ensure long service life in harsh and chemically aggressive conditions. -

Easy Operation and Maintenance

Open structure allows convenient filter belt cleaning, replacement, and routine inspection, reducing downtime and labor requirements.

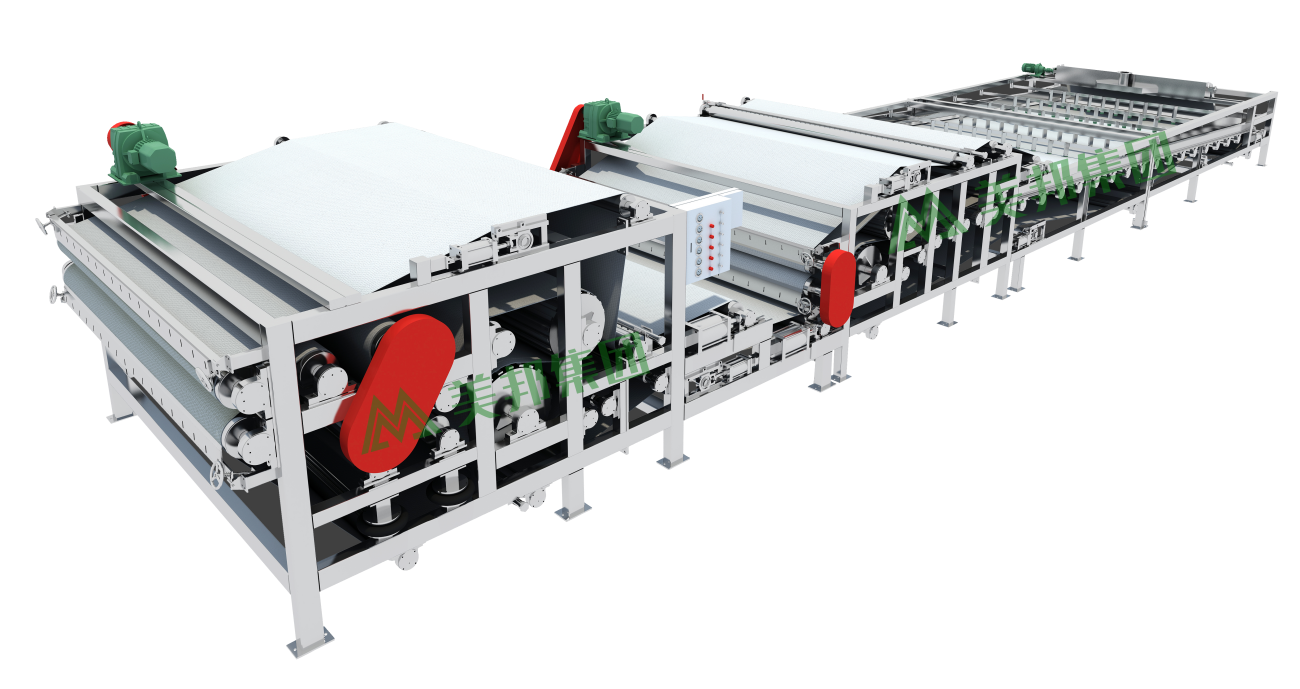

Working Principle

After proper conditioning in the flocculation system, industrial sludge is evenly fed into the four-belt filter press.

During operation, the sludge passes through several stages:

-

Gravity Dewatering Zone – Rapid removal of free water

-

Multi-Stage Pre-Pressing Zones – Gradual compression between multiple belts

-

High-Pressure Pressing Zones – Four belts apply strong squeezing and shear forces

Dewatered sludge cakes are continuously discharged, while the filtrate is collected and returned to the industrial wastewater treatment system.

Typical Industrial Applications

-

Industrial wastewater treatment plants

-

Chemical industry sludge dewatering

-

Food and beverage processing wastewater treatment

-

Brewery, paper mill, and fermentation industry sludge

-

High-strength and complex industrial sludge treatment

Product Advantages

-

High dewatering efficiency for industrial sludge

-

Lower sludge cake moisture content

-

Stable operation under continuous industrial workloads

-

Reduced sludge handling, transportation, and disposal costs

-

Reliable performance for complex industrial wastewater conditions

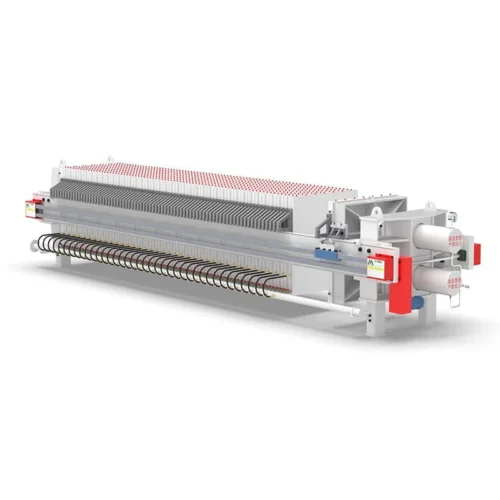

Optional Configurations

-

Automatic polymer dosing system

-

Online filter belt washing system

-

PLC control system with touch screen

-

Variable frequency drive (VFD)

-

Filter belts in different materials and widths

Why Choose Our Four-Belt Filter Press?

Our four-belt filter press is engineered to meet the practical demands of industrial wastewater treatment, offering efficient sludge dewatering, stable operation, and low operating costs. It is an ideal solution for industrial users seeking reliable and high-efficiency sludge dewatering equipment for chemical and food processing industries.

Applications This four-belt filter press is widely used in industrial wastewater treatment projects, including chemical wastewater treatment, food and beverage processing wastewater, pharmaceutical sludge dewatering, and other industrial sludge treatment applications.