What is plate and frame filter press

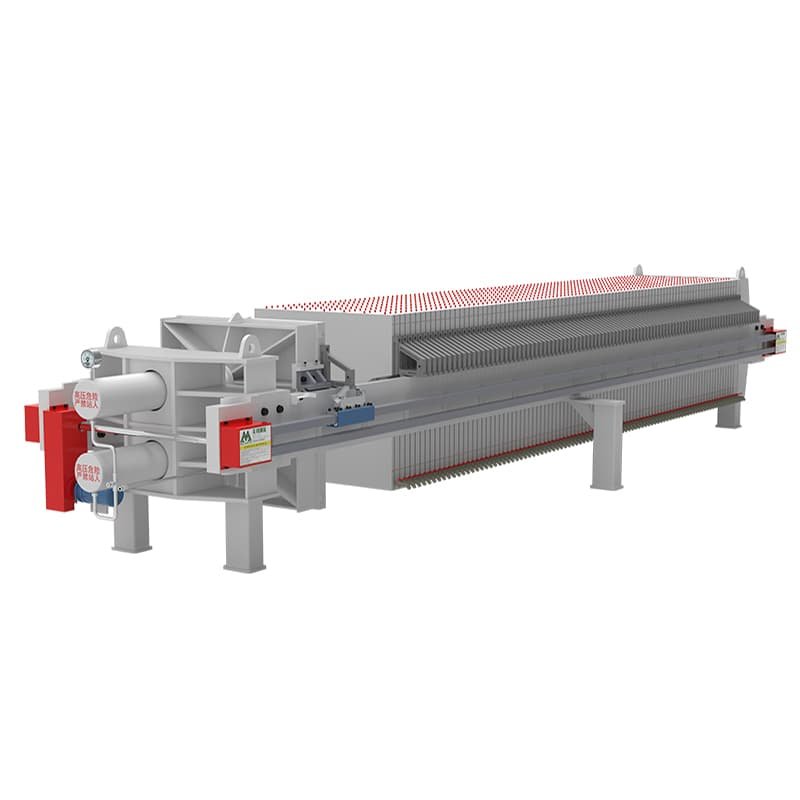

The plate and frame filter press is one of the most usual kinds of filter press equipment applied in solid-liquid separation. A series of filter plates and frames were arranged alternately with a filter cloth or paper in between. The plates are normally made from polypropylene, cast iron, or stainless steel, having grooves or channels to allow filtrate to flow out of the press.

A plate and frame filter press works in a manner such that the slurry mixture of solids and liquid is fed into the press, which then can be pumped between the plates. The liquid portion of the mixture, or filtrate, actually passes through the filter cloth or paper and falls into a tray or tank underneath the press while the solids remain between the plates.

After filtration, the press is opened and the accumulated solids-the filter cake-are removed from the plates. The filter cloth or paper is washed and replaced or cleaned and the press goes to the next filtration cycle.

Plate-and-frame filter presses can thus be widely applied in food and beverage, pharmaceuticals, chemicals, and even wastewater treatments, among others. They are ideal for various applications since they are flexible, show high efficiency in filtration, and are also simple to operate and maintain.

Plate and frame filter press type

There are a number of types of plate and frame filter presses that can be found in the market, and some of the common ones include:

- Manual Plate and Frame Filter Press: These are the most rudimentary kinds of plate and frame filter presses, where plates and frames are shifted manually for the operation of one cycle of filtration.

- Semi-automatic plate and frame filter press: this filter press makes use of hydraulic or pneumatic systems in advancing the plates and frames forward, and it is more automated than its manual counterpart.

- Automatic plate and frame filter press: in this kind of filter press, a completely automated electric or hydraulic system is employed which regulates the flow of the plates and frames, besides the filtration cycle.

- Recess Plate Filter Press: These are varieties of filter presses in which the plates are recessed; that is, they are concaved to hold the filter cake during filtration.

- Membrane Plate Filter Press: This filter press includes membrane plates, which are specially designed for higher filtration efficiency with better sealing than conventional filter plates.

Where appropriate, type selection of plate and frame filter press will depend on application specifics-such as type of solids and liquid, filtration efficiency required, and level of automation desired.

Plate and Frame Filter Press Application

Plate and frame filter presses represent one of the most common forms of filtration equipment in use today in solid-liquid separation applications. Typical applications for plate and frame filter presses include:

- Wastewater Treatment: Plate and frame filter presses are a very common piece of equipment in many wastewater treatment facilities as a means of removing solids and other impurities before discharge into the environment.

- Chemical Processing: Plate and frame filter presses are applied in chemical industries for solid-liquid separation in several chemical processing applications.

- Food and Beverage Processing: Plate and frame filter presses are utilized in food and beverage industries for the clarification of liquids, removal of impurities, and separating the solid and liquid fractions of a product, which could be juice, beer, and wine.

- Pharmaceuticals: Plate and frame filter presses serve widely in the pharmaceutical industry for filtering APIs, or Active Pharmaceutical Ingredients, along with other intermediate and final products.

- Mining and Mineral Processing: Plate-and-frame filter presses are applied in mining and mineral treatment processes to dewater slurries of coal, iron ore, and other precious metals.

In general, plate-and-frame filter presses represent a versatile and effective solution for a surprising number of applications requiring solid-liquid separation in many industries.