What is a Filter Press and How Does It Work?

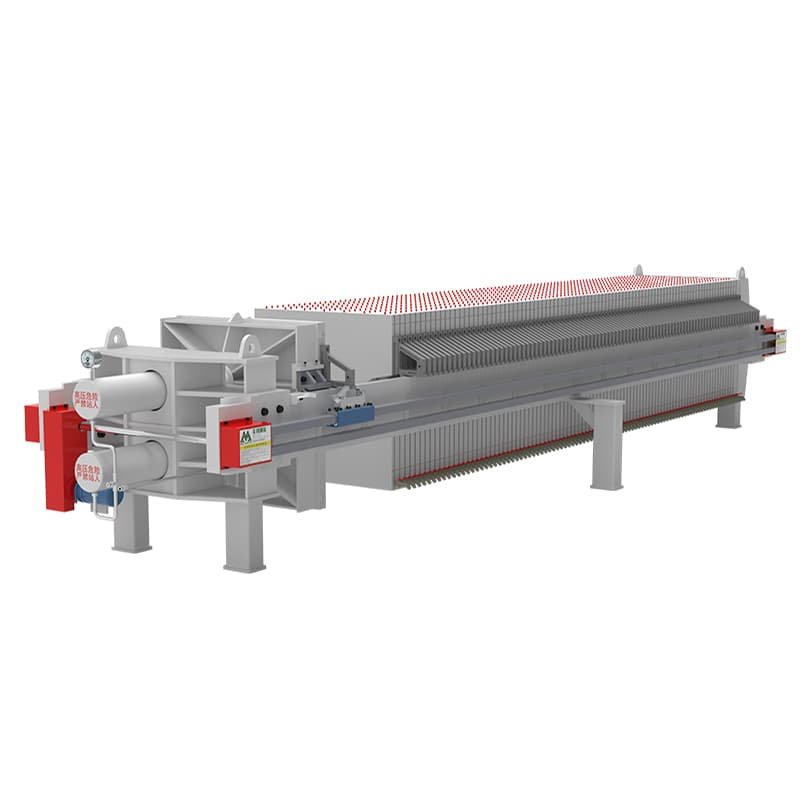

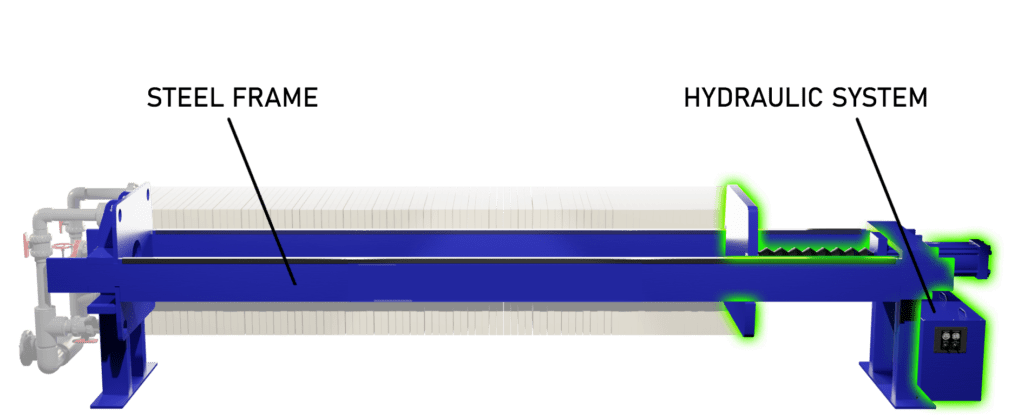

What is a filter press and how does it work? A filter press is an equipment utilized to separate liquids from solids in a large number of applications. Supported by five key elements: filter cloths, filter plates, steel frames, hydraulic systems, and manifolds. A filter press is designed to efficiently process large batches of pressurized slurry.

Filtration occurs at the filter cloth, a flexible material securely positioned by its corresponding filter plate

Multiple plates stack within a steel frame, clamped together by the hydraulic system.

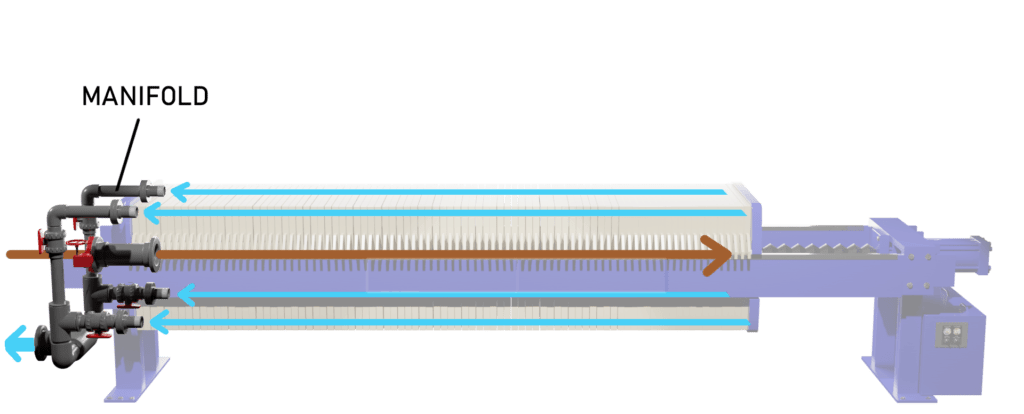

This plate stack creates a circuit for the liquid, beginning and ending at the manifold.

How Does It Work?

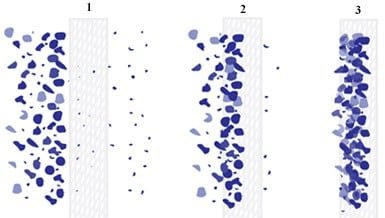

At the heart of the filter press is the filter cloth, which separates liquid filtrate from suspended solid particles. Initially some fine particles may pass through. As larger particles bridge the cloth openings, they form an initial layer that enhances filtration efficiency because of reduction of effective openings in the filter media. The distribution of solids within each chamber is uniform, and the solids compact closely in the feed cycle because of the given higher pressure.

By the end of the filtration cycle, dewatered filter cake fills each chamber completely. Each chamber is created by clamping two filter plates together, with filter cloth encasing the entirety of this cavity. The steel frame serves to align and hold the plates forming an interconnected system of chambers; each plate contributes to the overall capacity of the fixed-volume filter press.

Once the liquid has penetrated through the cloth membrane, the plates are specially designed to have an inner porting system that routes filtrate to the manifold. When the even-fill process is completed, the valve configuration of the manifold is reversed by the operator to close off the feed cycle and allow filtrate to exit the press through one point – the filtrate outlet.

When the filtration cycle is complete, the follower moves back down and the filter press can be discharged. Reclose the press to start a fresh batch.

What is it Used For?

Filter presses are applied to numerous applications on various industries. Examples are surface finishing, chemical engineering, mining, chemical manufacturing, food and beverage processing-they all use filter presses within their workflow. For more detailed information on how our team can help with your dewatering needs, please contact us.