Types of Filter Plates

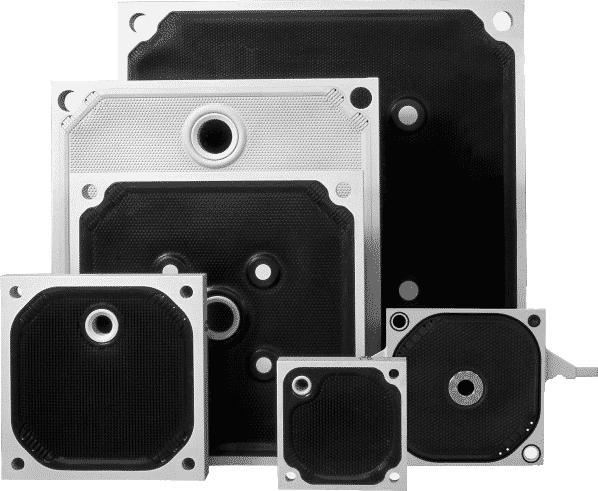

There are three basic types of filter press plates: recessed chamber, membrane squeeze(diaphragm squeeze), plate-and-frame.

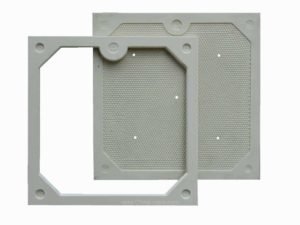

Recessed Chamber Filter Press Plates

These filter plates are used in a variety of recessed chamber filter press brands and represent the most commonly used plate.

- The filter plates are more robust and have a higher fill pressure than plates and frame.

- Gasketed, virtually leak free (CGR)

- Allows the mechanical shifting of plates.

- Non-gasketed available (NG)

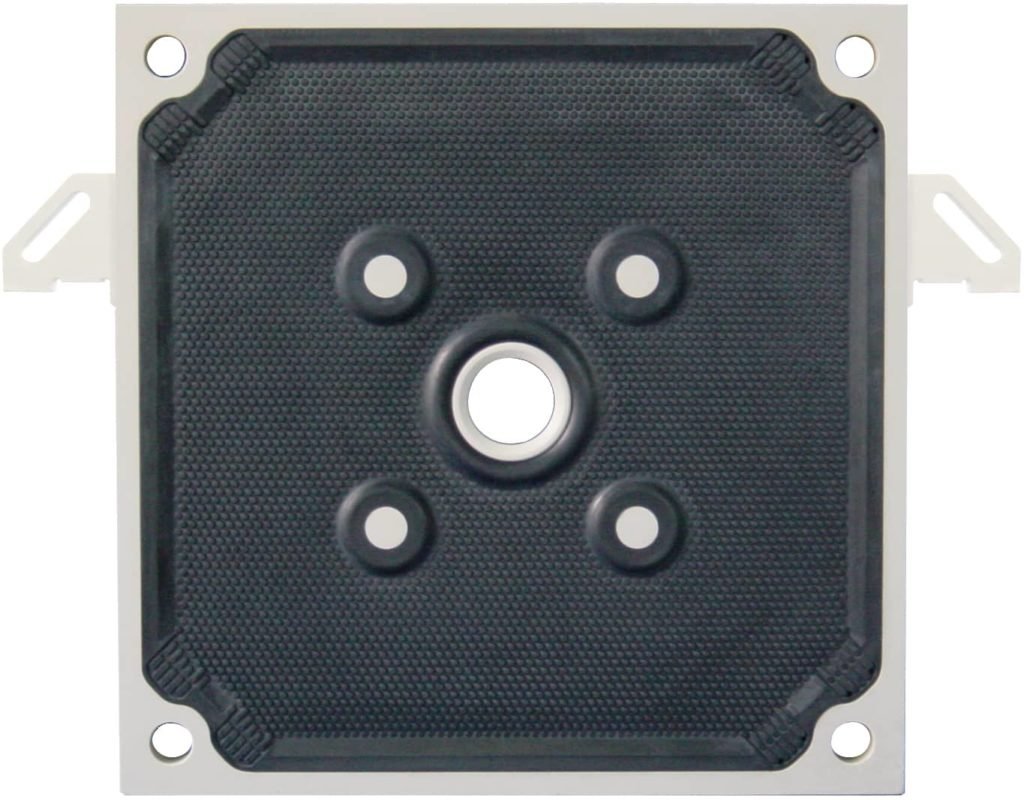

CGR vs. NG Filter Plates

“CGR” means “Caulked, Gasketed, Recessed chamber. CGR filter plates should result in nearly leak-proof filter press. Filter cloths for these plates are octagon shaped with a caulking rope or cord sewn into the edge of the cloth.

“NG” stands for “Non-Gasketed. ” NG cloth is quicker and easier to apply, but the downside is that, sometimes, there might be some dripping occurring when NG cloths are applied.

To learn more about filter cloths, check out our filter cloth page.

Membrane Squeeze Filter Plates (Diaphgragm Squeeze)

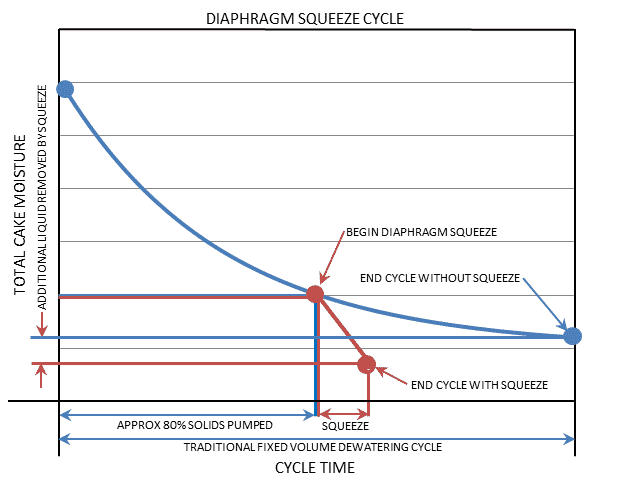

These are filter plates used in a membrane squeeze filter press and are designed for special applications. This type of plate also costs more than recessed chamber plates. Utilizing diaphragm/membrane squeeze filter press plates can result in drastic added fluid removal and/or cycle time reduction if the filter cake is compressible.

These are things that our Sales and Service Team keeps in mind when recommending membrane squeeze plates:

- The filter cake is compressible.

- Slurry is over the average solids

- Time is money – the time saved by the squeeze justifies more expensive equipment

- Slurry of a variable volume

As can be observed, on the average application 80% of the solids are pumped into the press during the first half of the cycle, where the remaining half is considered the consolidation stage. The addition of membrane squeeze abbreviates the cycle and reduces cake moisture content – see chart.

The result is increased throughput and/or better liquid recovery. Membrane squeeze can be added to a filter press by installing a suitable plate stack, a squeeze water manifold and a filter plate pressurization system. Typically membrane plates are interspersed with normal chamber plates in a “mixed pack” as illustrated in the photograph below.

Please call us to talk about which type of membrane squeeze plate may best suit your application. Replaceable diaphragms, for chemical incompatibility, are available in several materials of construction, including EPDM, NBR, Viton and more.

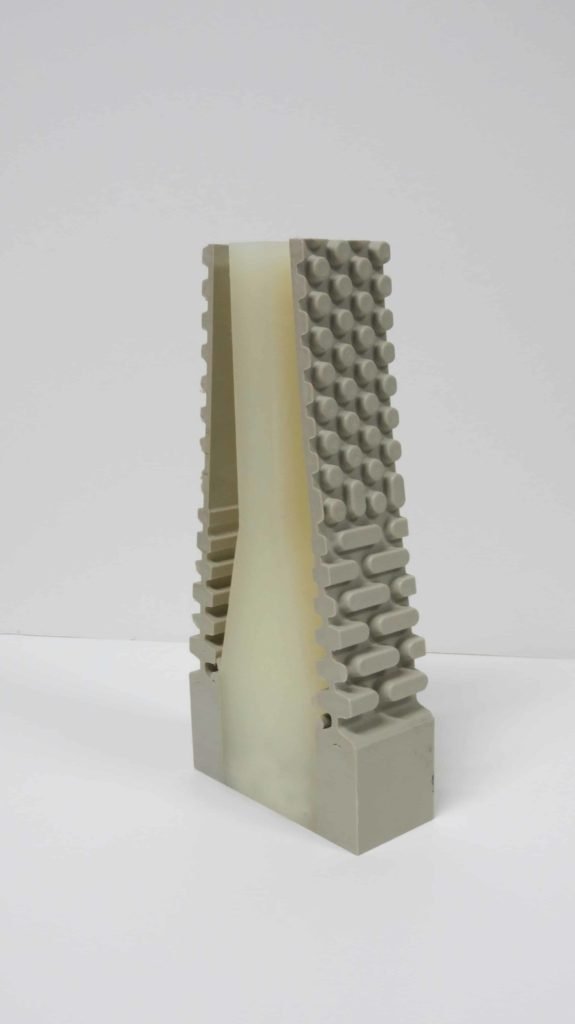

Plate and Frame Filter Press Plates

Plate and frame is the oldest of the filter plate designs, but is still useful in certain applications.

- Used where fine filtration is required and filter paper may be needed

- Provided with a thicker or thinner frame to allow operation with various thicknesses of filter cake

- Filter cloth drapes over plate

- Some leakage should be expected

- Normally operated at lower pressures

- Applications: Polishing and Specialty chemicals

Contact our Sales and Service Team to learn more or request a quote today.