Our Modern Manufacturing Factory

Our Modern Manufacturing Factory

We are a professional manufacturer of plate and frame filter presses and belt filter presses. We provide customized solutions with reliable quality and competitive pricing. Inquiries are welcome.

Top Filter Press Manufacturer

Plate and Frame Filter Press

We are a large-scale filter press manufacturer with in-house R&D, design, and manufacturing capabilities, making us a true source manufacturer. Our products are exported to multiple countries and regions and enjoy a strong reputation among customers worldwide. Green development, resource efficiency, and sustainability are the core values we uphold. Our filter presses are widely applied in municipal wastewater treatment, river dredging, mining wastewater treatment, construction wastewater treatment, fruit juice extraction, plant residue dewatering, coir pith production, and other dewatering and pollution control applications.

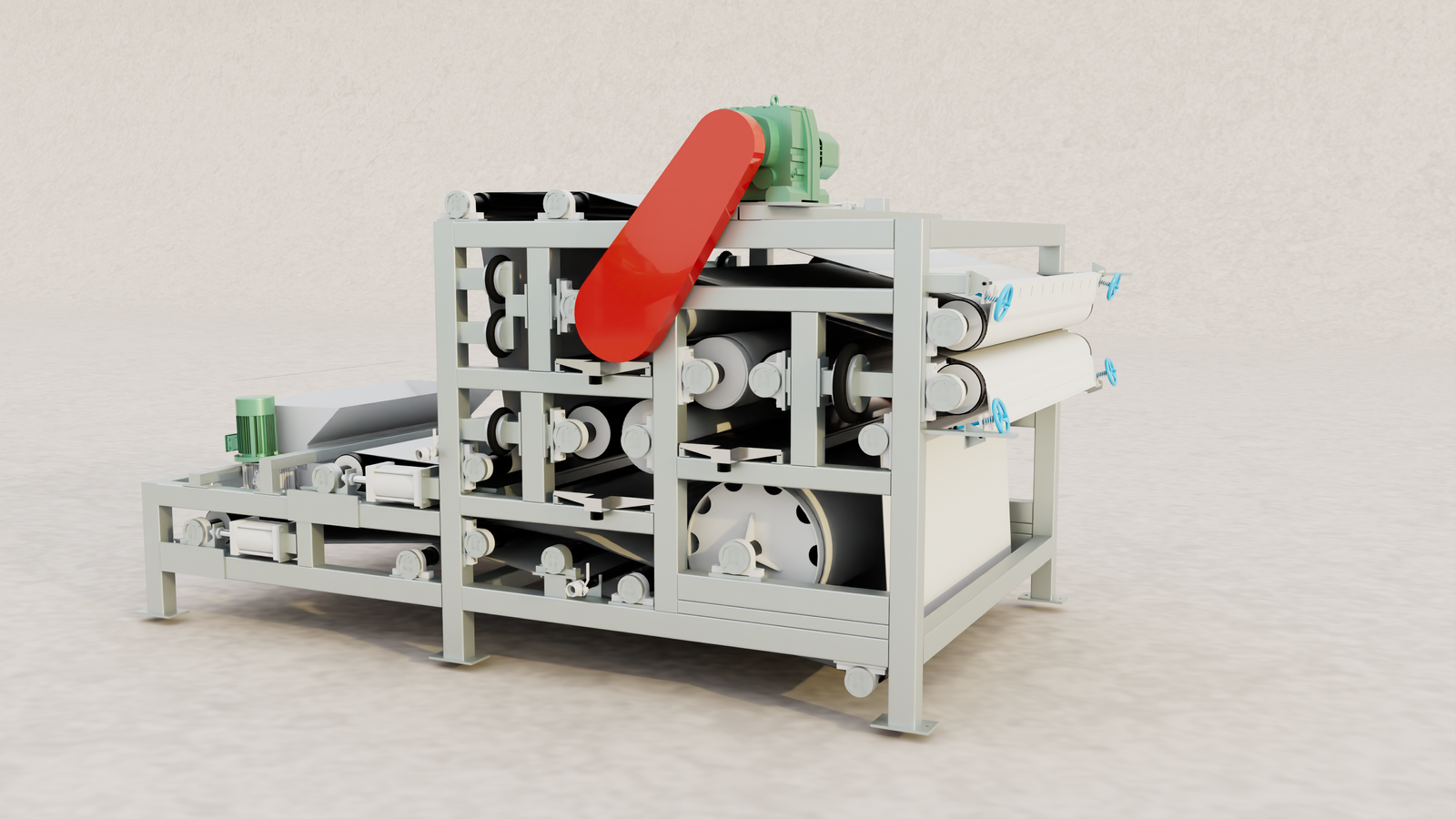

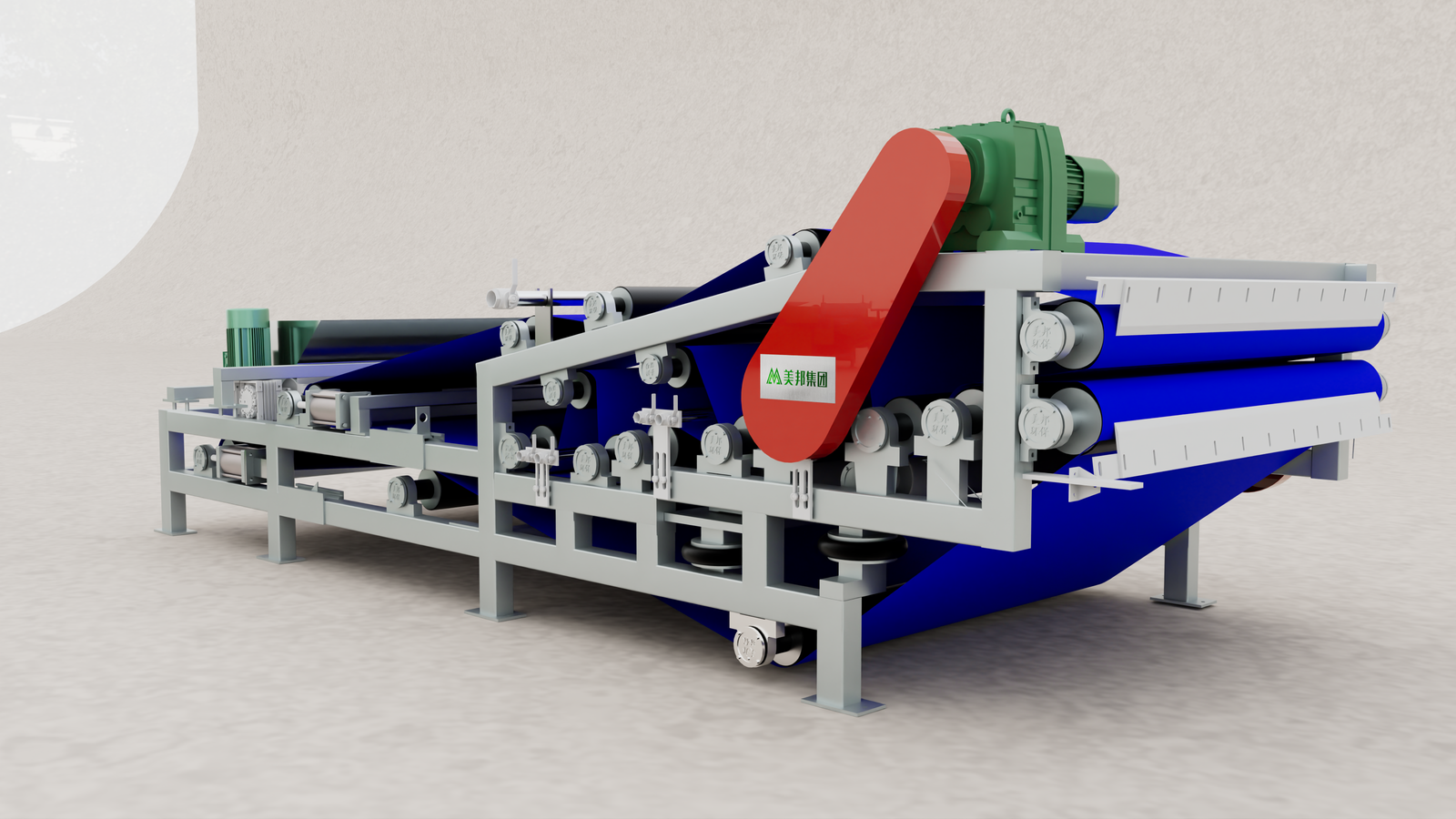

Belt Filter Press

Belt filter presses are used to remove water from liquid wastewater residuals and produce a non-liquid material referred to as “cake”.Dewatered residuals, or cake, vary in consistency from that of custard to moist soil. Dewatering serves,The general mechanical components of a belt filter press include dewatering belts, rollers and bearings,belt tracking and tensioning system, controls anddrives, and a belt washing system.

Belt Fiter Press

A belt filter dewaters by applying pressure to the bio solids to squeeze out the water. Biosolids sandwiched between two tensioned porous belts are passed over and under rollers of various diameters.Increased pressure is created as the belt passes over rollers which decrease in diameter. Many designs of belt filtration processes are available, but all incorporate the following basic features: polymer conditioning zone, gravity drainage zones, low pressure squeezing zone, and high pressure squeezing zones. Advanced designs provide a large filtration area, additional rollers, and variable belt speeds that can increase cake solids by five percent.

WHY CHOOSE US

Top Supplier For Plate and Frame filter press

We have a professional and experienced senior engineering team capable of providing specialized liquid–solid separation solutions for our customers. Our company employs dozens of senior engineers with solid theoretical knowledge and extensive practical experience. For large-scale projects, we can dispatch engineers overseas to provide on-site guidance and technical support.

Independent Research and Development

Our after-sales service team supports both domestic and overseas markets, providing installation, commissioning, and technical support for filter presses. The team consists of dozens of experienced professionals who can communicate effectively with customers in English.

Our overseas service team includes mechanical and electrical engineers as well as installation specialists. Based on project schedules and on-site requirements, we arrange appropriate personnel to provide on-site guidance and operation and maintenance training, ensuring stable operation and worry-free use for our customers.

Advanced Manufacturing Processes

Our agents are located worldwide, enabling closer communication with customers and a deeper understanding of their needs. During filter press operation, customers can directly contact their local agents for prompt and professional solutions tailored to specific conditions. If on-site engineering support is required, we can arrange technical personnel to provide service at the earliest opportunity.

More importantly, to ensure strict quality control, nearly all core components of our filter presses are manufactured in-house, except for electrical parts, valves, and motors. Even small components such as seals are produced by ourselves, ensuring consistent quality from the source.

Superior Service

We are a “Specialized, Refined, Differentiated, and Innovative” enterprise recognized in China. Our company maintains close technical exchanges and cooperation with leading global filter press manufacturers, and supplies filter plates, filter cloths, and other related accessories. We actively participate in internationally renowned industry technology exchange events each year, continuously adopting advanced technologies and concepts.

Customer feedback and trust drive our ongoing innovation and growth. We are committed to helping customers reduce operating costs and enhance productivity, and we will continue to deliver better solutions and higher levels of technological advancement.

Over the past 15 years, our company has established partnerships with governments and enterprises worldwide, delivering professional solutions for more than 200 production projects, municipal services, and water purification applications.