Membrane Filter Press

Membrane filter press-a variation of filter press-widely used in many industries, including applications related to solid-liquid filtration.

- Quality Materials

- Advanced Technology

- Variations of Filter Plates Available

- Full Automation

- Membrane Squeeze

- High Volume Capacity

Product Description

Membrane Filter Press-applied to industries

A Membrane filter press refers to a filter press variation widely used in many industries and applications that involve solid-liquid filtration. It is an advanced and specialized form of the conventional filter press integrating a flexible or elastic membrane onto the filter chamber. These membranes may be of different materials, including rubber or elastomers.

Membrane filter presses are widely applied in various industries dealing with wastewater treatment, chemical processing, mining, pharmaceuticals, and even food and beverages, among others, for which high efficiency of solid-liquid separation is required, along with reduced environmental impact. Considerably improved the overall effectiveness of the production process in industry.

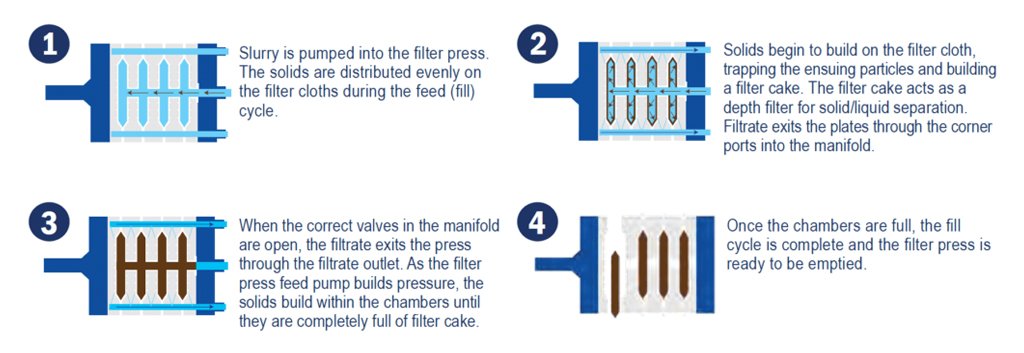

How Does a Membrane Filter Press Work?

- Charging the Filter Chamber

- Initial Filtration

- Membrane Inflation

- Improved Dewatering

- Final Filtration

- Cake Discharge

The key benefits of membrane filter presses include:

Higher Filtration Efficiency:

Compared to conventional filter presses, in membrane filter presses the cake dryness is higher. Thus, liquid waste is minimized.

Shorter Cycle Times:

Due to an additional stage of membrane squeezing, the cycle times become shorter and productivity increases.

Better Cake Quality:

The membrane aids in the formation of a filter cake that may be more homogeneous and predictable, making it easier to handle and dispose of.

Minimum Environmental Impact:

Membrane filter presses minimize environmental impact by providing drier filter cakes and reducing liquid wastes from filtration processes.